Welding method and application of plastic toys

There is a large demand for plastic toys in the market. What are the common welding methods? When it comes to plastic, everyone is familiar with it. From children's toys to instrument containers, from computer casings to car parts, from toothbrush tubes to aircraft parts, plastics are everywhere in our lives.

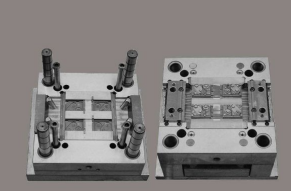

Injection molding is the most commonly used method in plastics processing. This method is suitable for all thermoplastics and some thermosets, and does not produce as many plastics as other molding methods. As one of the main tools for injection molding, the injection mold has a low level of quality accuracy, manufacturing cycle and production efficiency in the injection molding process.

Responsiveness and speed in market competition.

During the production process, the plastics coming out of different injection moulds are often welded. So, what are the methods of welding plastic toys?

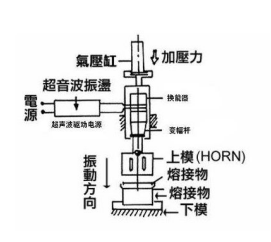

1. Ultrasonic welding machine welding

Ultrasonic welding machines use high frequency mechanical energy to soften or melt the thermoplastic at the joint.

When the pressure of the connected part is fixed, and the frequency usually passes the ultrasonic vibration of 20-40 kHz, the transducer converts the high-power vibration signal into the corresponding mechanical energy. When the joint is rubbed violently, high heat is generated, and the molecules are alternately fused to obtain a welding effect.

The ultrasonic welding process is fast, the welding time is less than 1 second, and the automation is easy. The use of automatic ultrasonic welding by plastic toy manufacturers can improve production efficiency and help enterprises transform and upgrade.

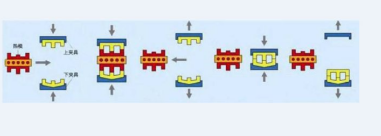

2. Hot plate machine welding

Features of plastic toy hot plate welding machine:

Simple, suitable for welding between large areas of plastics. Use a hot plate to quickly soften the two sides that need to be welded. After unplugging the hot plate, use pressure to fuse the plastics on both sides, and cool to complete the welding.

Disadvantages: The cycle is long, the plastic is easy to stick to the electric heating plate, the cleaning is difficult, and the pollution is large.

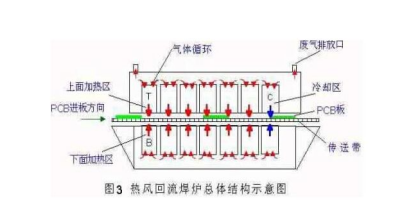

3. Hot air welding

Advantages: Lightweight, but difficult to operate.

The hot air melts the welding wire of the same material at the weld to complete the welding.

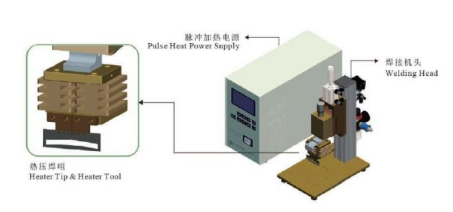

The two films are crimped, and the welding is completed with the instantaneous heat generated by the nichrome wire.

-

What if the product is damaged...

-

What is the ultrasonic matchin...

-

Which ultrasonic plastic weldi...

-

Disposable mask ear band ultra...

-

Various situations of ultrason...

-

Acrylic and which material is ...

-

The more important thing of ul...

-

Ultrasonic plastic welding mac...

-

Application of ultrasonic clea...

-

Solutions to common welding pr...

-

Use ultrasonic welding to do t...

-

What are the applications of u...

-

Welding method and application...

-

What should I do if the "ultra...

-

How to solve the root cause of...

-

Will "Qingyuan Ultrasonic Tran...

-

Three matters needing attentio...

-

Analog integrated circuit ultr...

-

Do you know the propagation ch...